Expanded sheet steel is a versatile substance Employed in different industries for different apps because of its energy, toughness, and flexibility. On this page, we will delve deep in to the manufacturing means of expanded sheet steel, Checking out the ways associated as well http://news-about-ferrous-metal-products-mmdh716.yousher.com/trenirovki-s-pvl-osobennosti-i-rekomendacii-dla-pohudenia as strategies utilised to generate this one of a kind materials.

Introduction to Expanded Sheet Metal

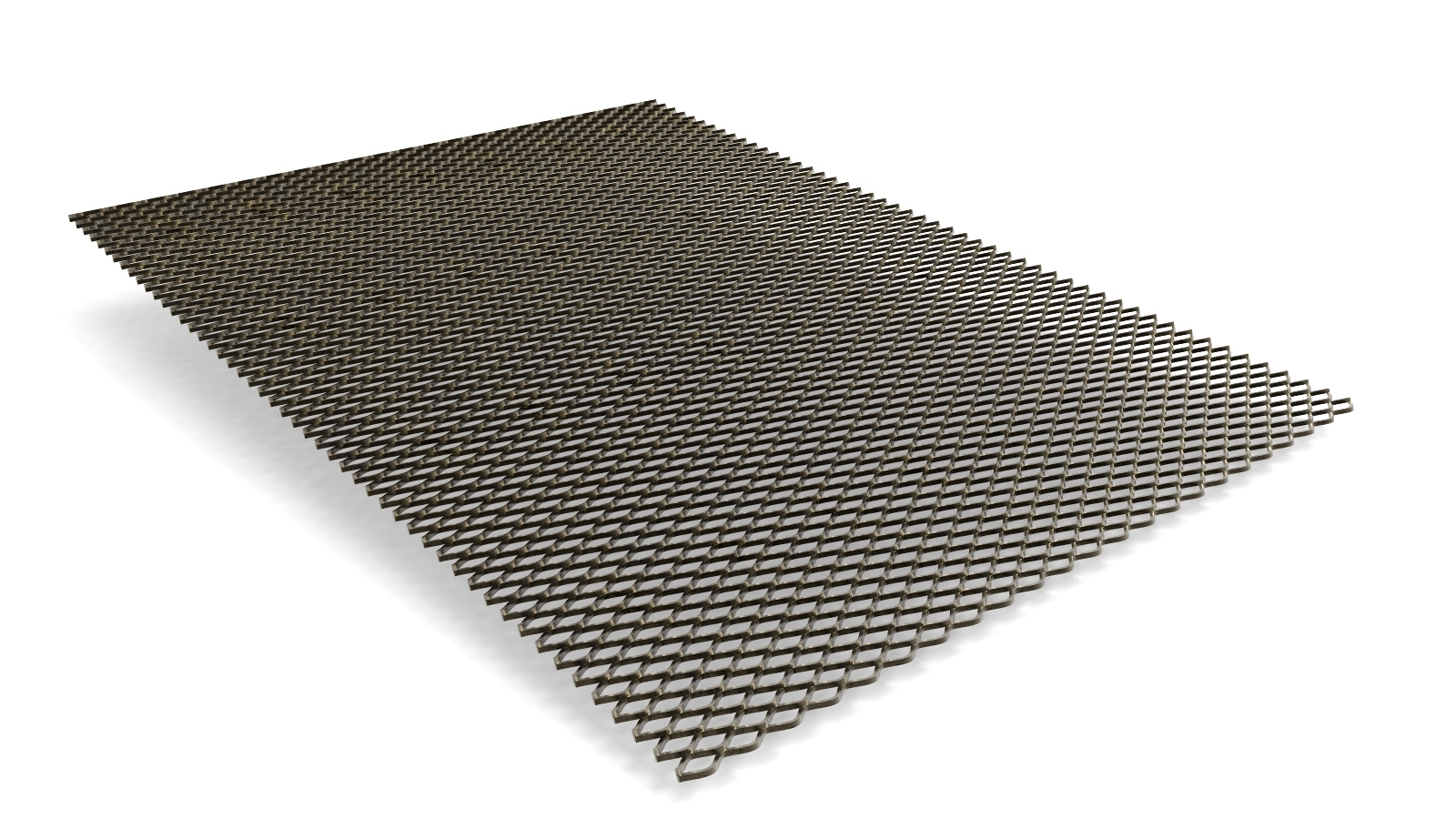

Expanded sheet metal can be a form of steel sheet that has been processed through a number of reducing and stretching functions to produce a sample of diamond-shaped openings. This method brings about a cloth that is certainly much better and much more rigid than common sheet metallic whilst still maintaining a lightweight and versatile mother nature.

What is Expanded Sheet Metal?

Expanded sheet steel is developed by cutting slits in a metallic sheet and after that stretching it to variety diamond-formed openings. This process raises the area region of the material, which makes it stronger and even more strong than frequent sheet steel.

Why Opt for Expanded Sheet Metallic?

Expanded sheet metallic presents numerous pros above common sheet steel, like enhanced toughness, rigidity, and flexibility. It is also a lot more lightweight and price-powerful, rendering it a great option for an array of applications.

The Manufacturing Process

The production technique of expanded sheet steel entails quite a few actions which can be carefully executed to make sure the quality and consistency of the final product or service. Let us acquire a closer evaluate Every stage of the process:

1. Substance Selection

The initial step in the producing method is picking the appropriate content for the expanded sheet steel. Differing kinds of metals can be employed, which include steel, aluminum, chrome steel, and copper, based on the wanted properties of the final products.

2. Cutting

Once the fabric has actually been picked, it really is Minimize into sheets of the specified dimension applying specialized chopping resources like shears or laser cutters. The sheets are then cleaned and ready for the subsequent phase of the procedure.

3. Slitting

In this phase, slits are created within the steel sheets utilizing a slitting device or push. The slits are strategically placed to create a precise pattern that may be expanded later on in the process.

4. Stretching

After the slitting course of action is total, the steel sheets are fed into an expanding device that stretches them in the two directions to make the diamond-shaped openings attribute of expanded sheet metal. The quantity of stretching used establishes the scale and shape in the openings.

5. Flattening

Once the stretching method is completed, the expanded sheets are flattened making use of rollers or presses to get rid of any wrinkles or imperfections brought on for the duration of expansion. This action makes certain that the sheets are easy and uniform in thickness.

6. Cutting to Size

The ultimate step within the producing approach involves slicing the expanded sheets to their closing dimensions utilizing precision reducing resources. This ensures that Each individual sheet satisfies the expected specifications for its supposed software.

FAQs about Expanded Sheet Metal

Here are some frequently asked questions on expanded sheet metal:

1. What are some typical apps of expanded sheet metallic?

Expanded sheet metallic is used in several industries for programs which include fencing, grating, filters, screens, partitions, and attractive applications.

2. Is expanded sheet metal corrosion-resistant?

Yes, dependant upon the style of material utilised (such as stainless-steel or aluminum), expanded sheet steel can be highly immune to corrosion, making it suitable for outdoor use.

3. Can expanded sheet metal be painted or coated?

Yes, expanded sheet steel may be painted or coated with protecting finishes to improve its overall look and durability whilst supplying extra resistance to corrosion.

4. How can expanded sheet metallic Look at to perforated sheet metal?

Expanded sheet metallic normally has larger openings than perforated sheet metallic and delivers bigger energy and rigidity resulting from its exclusive production process.

5. What factors should be regarded When picking expanded sheet metallic for a selected application?

When deciding upon expanded sheet metallic for a specific application, components including substance variety, thickness, opening sizing, pattern style and design, complete, and environmental circumstances should be taken under consideration.